World renowned

Their unique and stylish designs have turned heads since 1969. Premium quality and craftsmanship goes a long way - once you hold a pair of these frames in your hand you'll understand.

Exclusive to your Polegate store!

Visit Sophia and her team to view this stunning collection up close.

Quality you can feel

Once you hold a Cutler and Gross frame, you'll know what premium feels like.

Unique and stylish designs

The styles available really are unique, a real conversation starter.

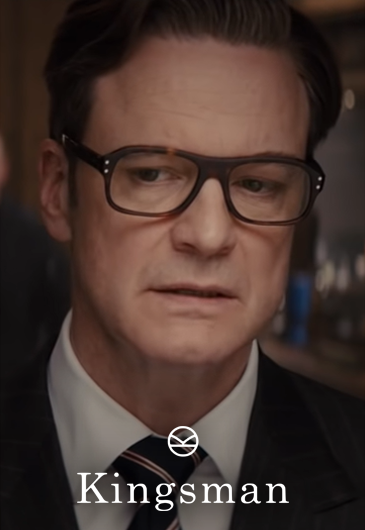

Featured on the big screen

Recognise them?

If you've seen the Kingsman movies, you'll have noticed the iconic Cutler and Gross styles - that distinctive shape is hard to forget and there is in fact a whole Kingsman collection available.

Other celebrities who have chosen Cutler and Gross include Madonna, Rihanna, Lady Gaga, Kate Moss, Michael Fassbender, Lily Allen, Victoria Beckham, Tinie Temper, Bill Nighy and Keira Knightley to name but a few!

Other celebrities who have chosen Cutler and Gross include Madonna, Rihanna, Lady Gaga, Kate Moss, Michael Fassbender, Lily Allen, Victoria Beckham, Tinie Temper, Bill Nighy and Keira Knightley to name but a few!

Founded in 1969

Cutler and Gross was established in 1969 by opticians and friends, Graham Cutler and Tony Gross. They'd first met at Northampton College whilst studying optometry during the early 60s.

Their partnership went from small and humble beginnings to becoming industry leaders in eyewear. Hand-crafted in Italy, these designs have stood the test of time, and today, we see Cutler and Gross everywhere with celebrities choosing these styles for their striking shape and sheer quality. Cutler and Gross create frames that are built to last - they're classed as optical architects in pursuit of a product so iconic that no visible logo or branding on is necessary.

Their partnership went from small and humble beginnings to becoming industry leaders in eyewear. Hand-crafted in Italy, these designs have stood the test of time, and today, we see Cutler and Gross everywhere with celebrities choosing these styles for their striking shape and sheer quality. Cutler and Gross create frames that are built to last - they're classed as optical architects in pursuit of a product so iconic that no visible logo or branding on is necessary.

Arrange a visit! Drop by or: